Lubricant Solutions

A Variety of Lubricant Options From Permatex

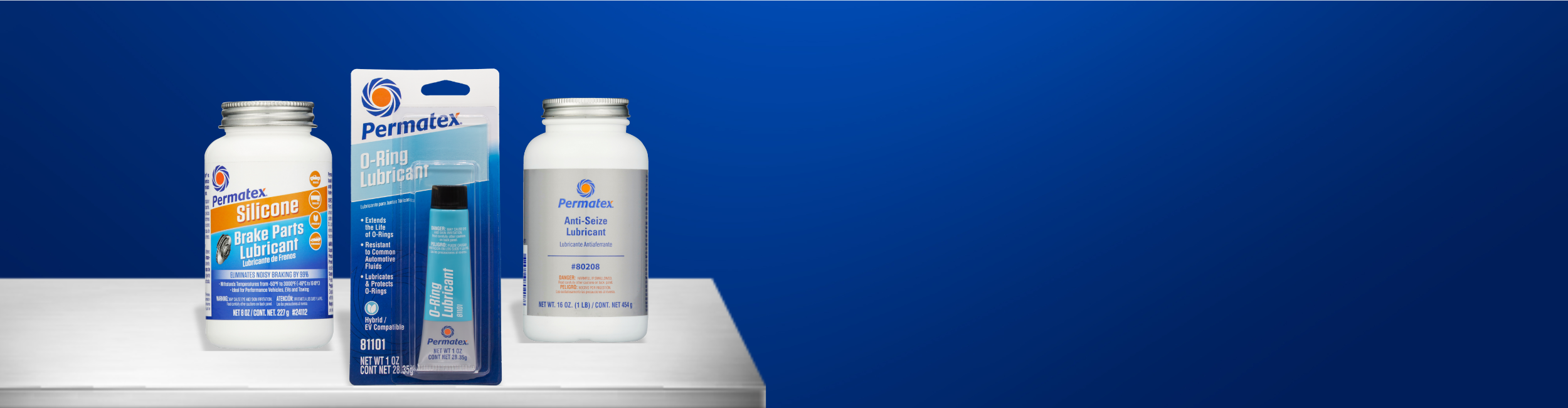

Anti-Seize Lubricants

Anti-Seize Lubricant is designed to prevent seizing, galling, and corrosion on metal parts exposed to high temperatures and pressure. These lubricants provide a protective barrier on metal parts that makes parts easier to assemble, disassemble, and maintain, resulting reliable performance even in harsh conditions.

Brake Parts Lubricants

Brake Parts Lubricants are designed for every vehicle. Permatex Brake Parts Lubricants reduce noisy braking, protect brake hardware from seizing and galling and will not cause rubber swell.

Specialty Lubricants

Provide high-performance protection and smooth operation for critical parts. Designed for automotive, industrial, and mechanical use, they reduce friction, prevent rust, and ensure long-lasting durability under tough conditions.

Explore Anti-Sieze lubricants

Anti-Seize Lubricants are ideal for preventing seizing, galling, and corrosion on threaded fasteners and metal parts, especially in high-temperature or high-pressure environments.

Explore Brake parts lubricants

Permatex Brake Lubricants are ideal for reducing friction, preventing squeaks, and ensuring smooth operation of brake components, including calipers, pads, and hardware.

Explore specialty lubricants

Permatex Specialty Lubricants are ideal for providing tailored lubrication solutions for specific applications, such as high temperatures, extreme pressures, or specialized machinery, ensuring smooth operation and reducing wear.

5th Wheel Grease

- Graphite for heavy duty applications

- Premeasured grease, easy to apply

- Effective at extreme temperatures and environmental conditions

Frequently asked questions

Find answers to common questions about Lubricants.

Permatex Brake Parts Lubricants reduce friction, prevent corrosion, and minimize noise in brake components, ensuring smooth and efficient braking performance. They are specifically designed to withstand high temperatures and harsh conditions without breaking down or washing away. These lubricants are applied to caliper slides, pins, and contact points where metal moves against metal to prevent sticking and uneven wear. Proper application of brake parts lubricants helps extend the lifespan of braking components and enhances overall vehicle safety.

No, you should only use high-temperature, non-petroleum-based lubricants specifically designed for brake systems. Petroleum-based greases can cause rubber components, such as caliper seals and bushings, to swell, soften, or degrade over time. This deterioration can lead to brake system malfunctions, including sticking calipers, uneven brake wear, and reduced braking performance. Using the wrong lubricant may also increase the risk of brake failure, compromising vehicle safety.

Apply brake parts lubricant to caliper slide pins, backing plates, and contact points where brake pads move to ensure smooth operation and prevent sticking. Proper lubrication in these areas helps reduce noise, minimize wear, and extend the lifespan of braking components. However, avoid applying lubricant on the friction surface of the pads or rotors, as this can reduce braking effectiveness and create safety hazards. Contaminated brake pads or rotors may lead to reduced stopping power, increased stopping distances, and potential brake failure.

Lack of lubrication can cause brake squealing, uneven wear, and sticking calipers, leading to premature component failure and reduced braking efficiency. When caliper slides and other moving parts are not properly lubricated, they may seize or stick, preventing the brake pads from retracting correctly after braking. This can result in excessive heat buildup, accelerated pad and rotor wear, and a spongy or unresponsive brake pedal. Over time, these issues can compromise the overall braking performance, increasing the risk of costly repairs and potential safety hazards on the road.

Anti-seize is used on threaded fasteners, bolts, and components exposed to extreme heat and corrosion to prevent seizing, galling, and rust. It forms a protective barrier that reduces metal-to-metal contact, making future disassembly easier and preventing wear caused by friction. This is especially useful in high-temperature environments, such as exhaust systems and engine components, where heat can cause metal parts to fuse together. By applying anti-seize, you can reduce the risk of broken bolts, stripped threads, and costly repairs.

Common applications include spark plug threads, exhaust bolts, wheel hub assemblies, and lug nuts to ease future disassembly. It is particularly helpful in areas exposed to heat, moisture, and corrosion, where rust buildup can make parts difficult to remove. For instance, applying anti-seize to spark plugs prevents them from seizing in the cylinder head, reducing the risk of thread damage. However, it should always be used in moderation, as excessive application can attract dirt and debris, which may cause additional issues.

Permatex Aluminum Anti-Seize, is suitable for general-purpose applications and is often preferred for preventing galvanic corrosion between different types of metals, such as aluminum and steel. Permatex Copper Anti-Seize is ideal for high-heat applications like exhaust systems because it has excellent electrical conductivity and can withstand extreme temperatures. Permatex Nickel Anti-Seize is for high heat application where copper is prohibited. The choice depends on the specific application, as copper-based products should not be used on aluminum components due to the potential for galvanic corrosion. For most standard automotive maintenance needs, aluminum-based anti-seize is a safe and versatile option.

No, anti-seize is designed to be long-lasting and resistant to moisture and corrosion, providing extended protection for threaded components. However, excessive exposure to high-pressure washing, extreme heat cycles, or harsh environmental conditions may gradually reduce its effectiveness. In such cases, reapplication may be necessary during routine maintenance to ensure continued protection against seizing and rust. Using the appropriate anti-seize formula for the specific application can also enhance its durability and performance under demanding conditions.

Permatex O-Ring Lubricant is a silicone-based formula designed to ease the assembly of O-rings and seals. It provides protection against common failures caused by heat and chemicals, ensuring the longevity and reliability of the components. This lubricant is particularly useful in automotive and industrial applications where O-rings are exposed to harsh conditions. By applying this lubricant, you can prevent damage during installation and operation, leading to improved performance and reduced maintenance costs.

To apply Permatex O-Ring Lubricant, first ensure that the O-ring and its mating surfaces are clean and free from debris. Apply a thin, even layer of the lubricant to the entire surface of the O-ring using a brush or your fingers. Be cautious not to over-apply, as excess lubricant can attract dirt and contaminants. Once lubricated, proceed with assembling the O-ring into its housing, ensuring it seats properly to prevent leaks or damage.

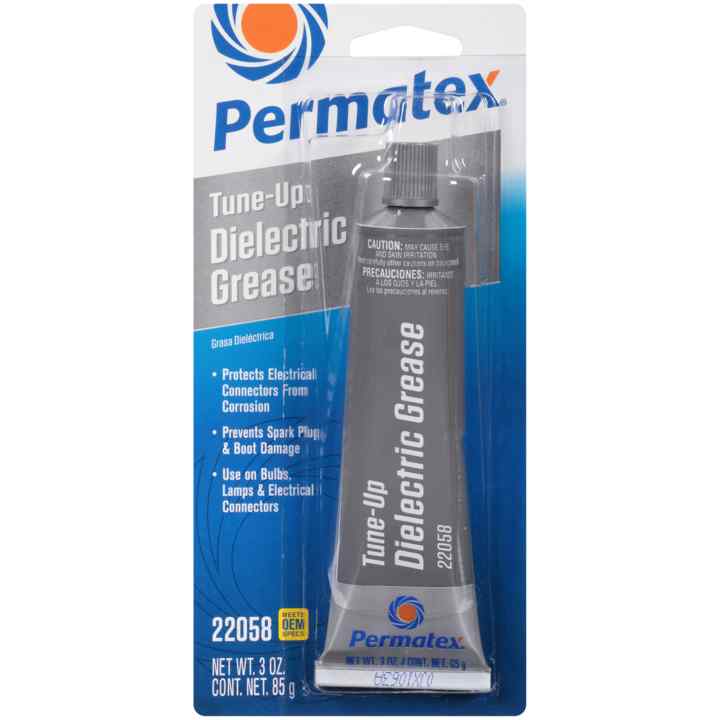

Permatex Dielectric Grease is designed to protect electrical connections and wiring from salt, dirt, and corrosion. It extends the life of bulb sockets, prevents voltage leaks around electrical connections, and stops spark plugs from fusing to boots. This grease is essential for modern high-energy ignition systems to ensure optimal performance and longevity